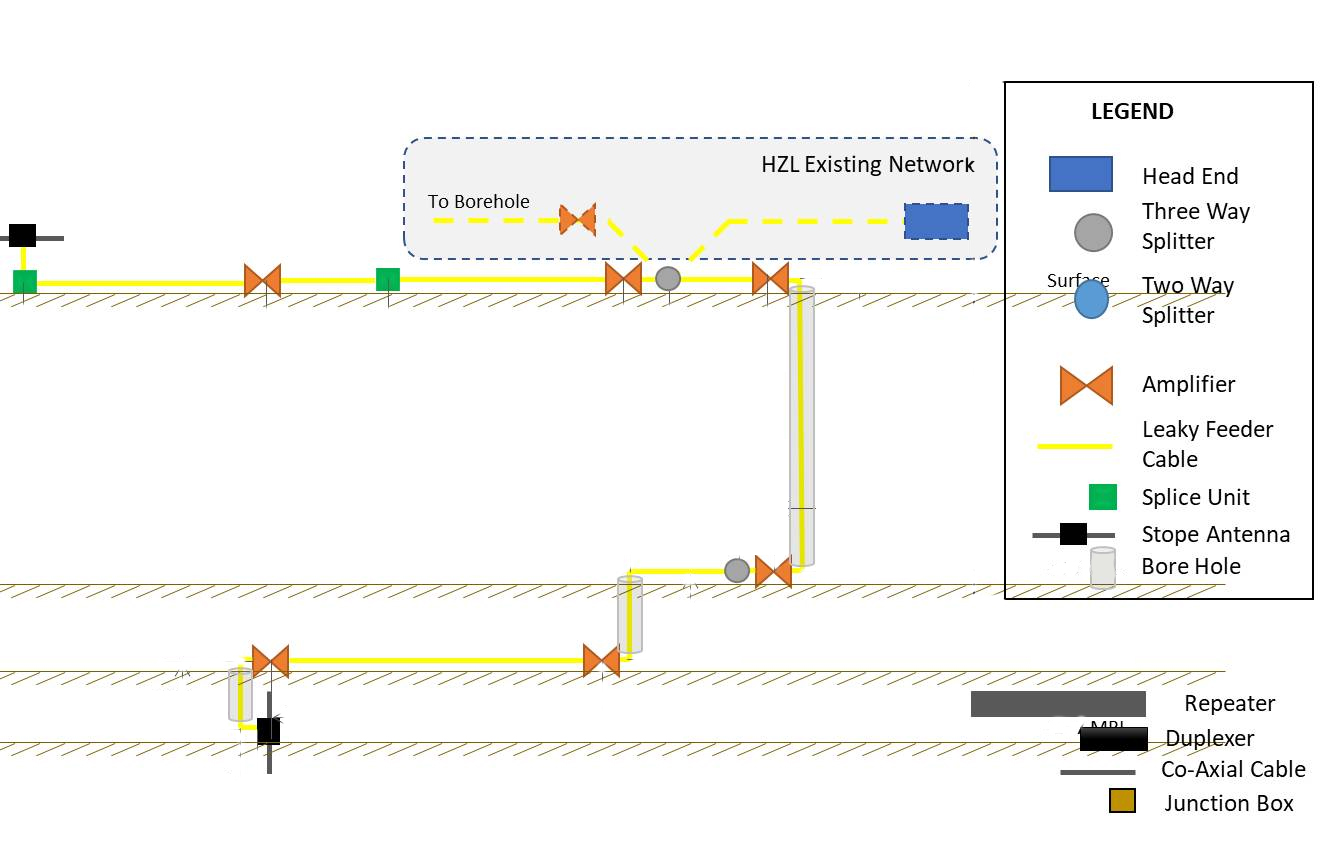

Leaky Feeder Cable of Becker-Varis along with Amplifiers and Headend and other materials were used to established the communication in the underground tunnel.

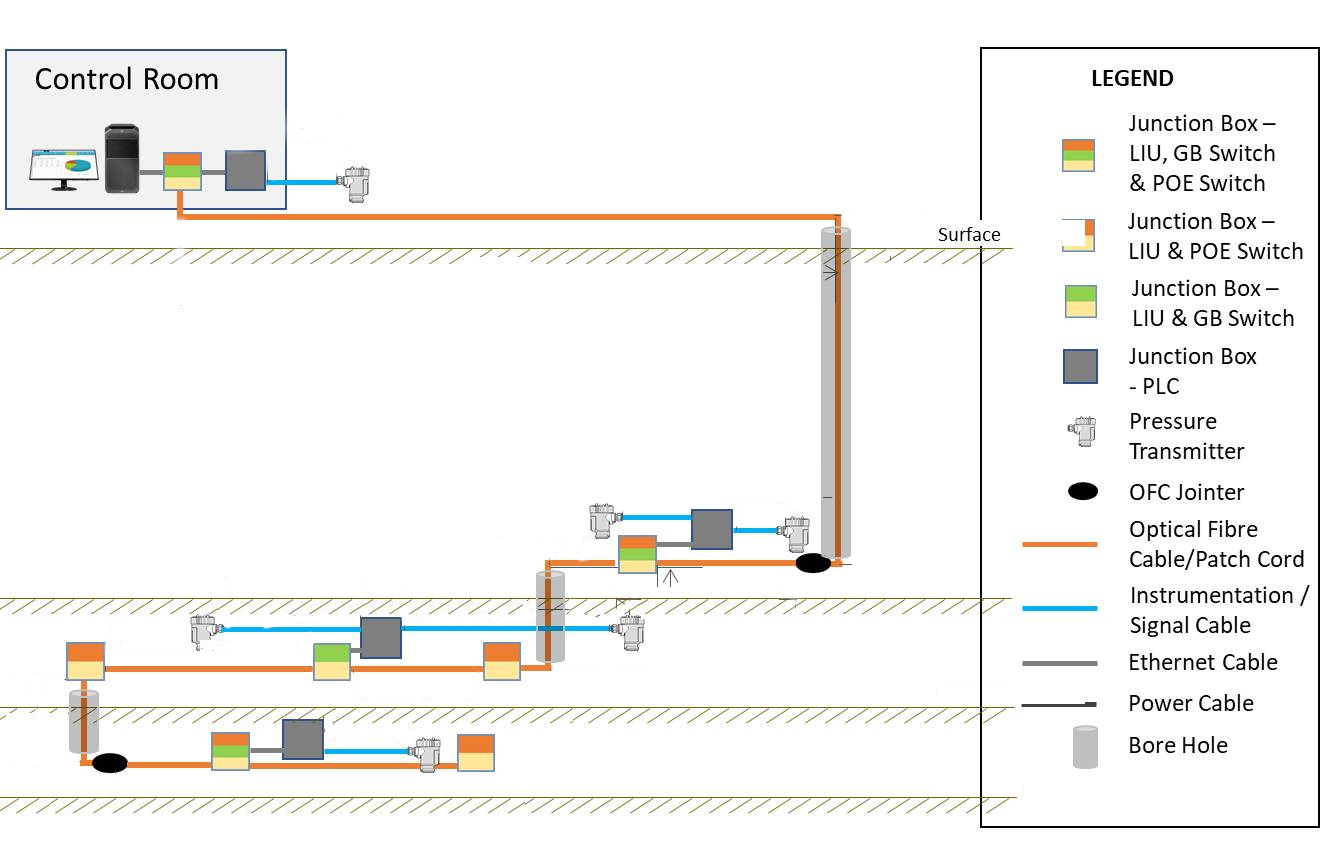

Allen Bradley PLCs and Vega Pressure Transmitter for measuring the pressure of slurry in the pipeline & controlling the flow with SCADA System Software.

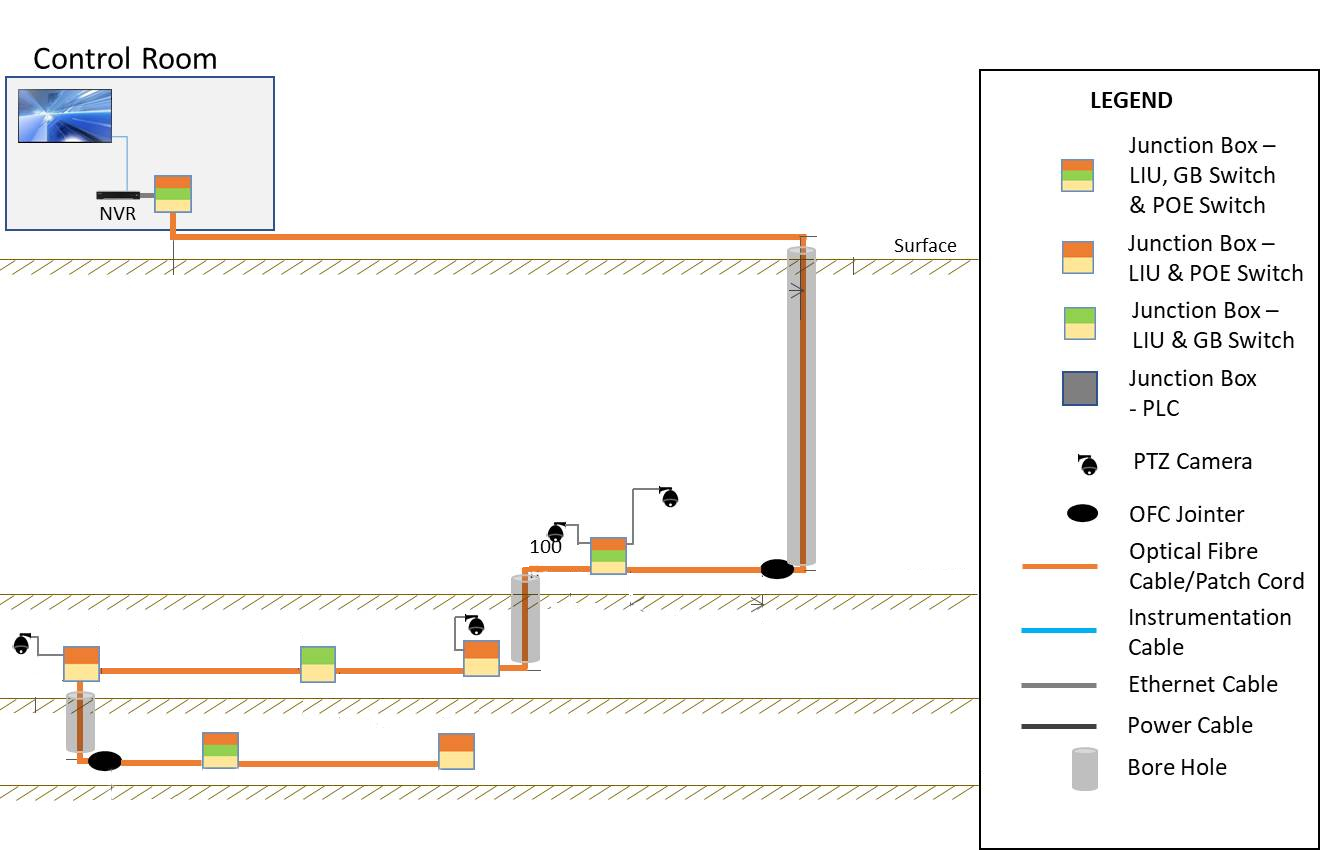

Bosch IP Cameras with Long IR Distance coverage , Bosch Video Server , Cisco Switches along with laying of OFC Fibre (IP) was done for installation of CCTV network in the UG Mine.

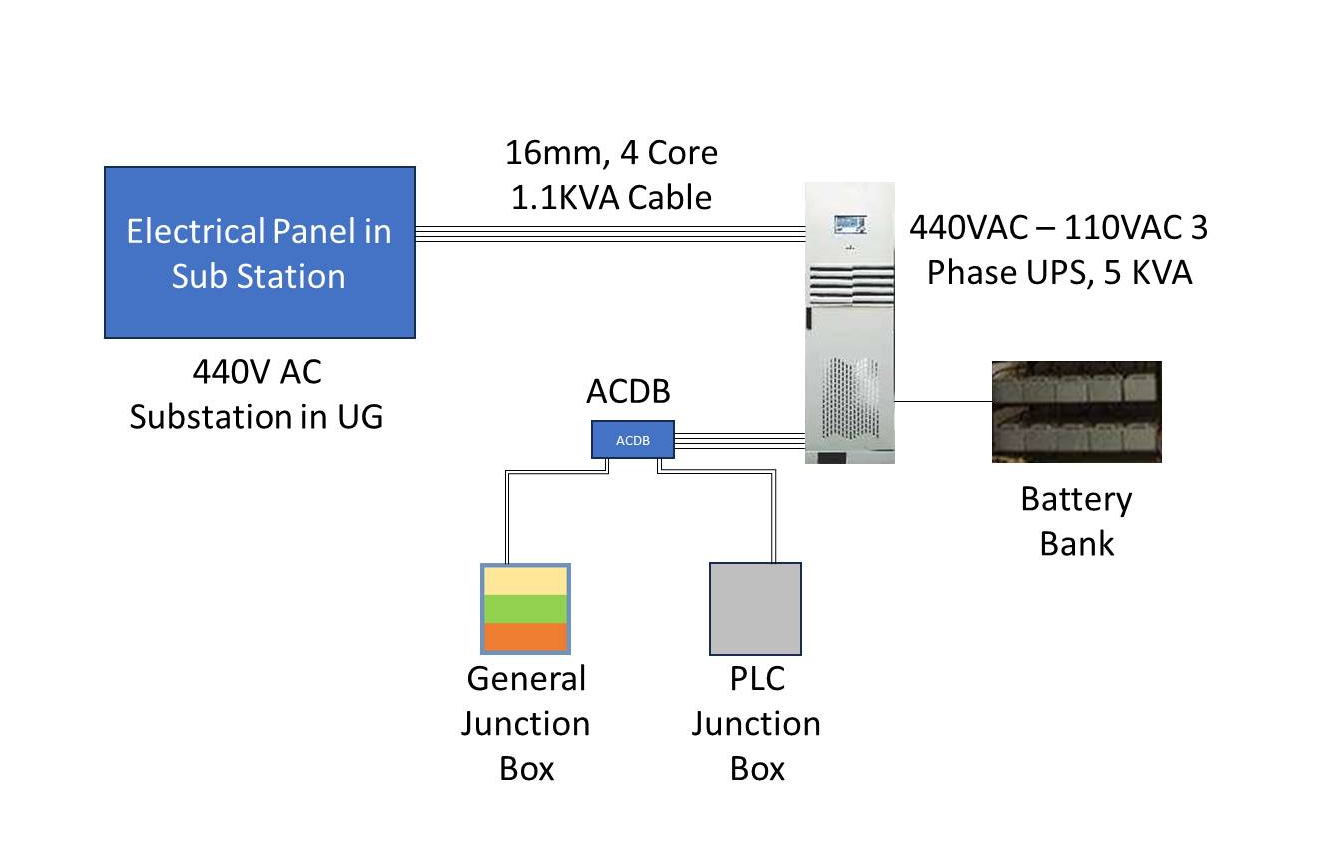

Hitachi-Hirel 440V UPS are installed and connected to existing Substations using 1100V 4cx16mm Double Armoured cable.